Dirty Data is No Longer a Barrier: An AI-First Approach to Supply Chain Data Quality

The Problem Every Supply Chain Leader Knows Too Well

You’ve invested in a data lake. You’ve connected your ERP, WMS, and procurement systems. In theory, you now have a single source of truth.

But here’s the catch: the data inside it is messy. Inconsistent product codes, duplicate supplier records, mismatched addresses, missing fields—it’s chaos. And when the data is dirty, AI and analytics initiatives stall.

The traditional fix—months-long data cleansing projects—is slow, costly, and simply doesn’t scale. It’s no wonder that 81% of AI professionals admit their companies don’t handle data quality issues well.

As one expert puts it: “Bad or outdated data is worse than having no data at all.”

At xChangeFlow, we believe it doesn’t have to be this way. Dirty data is no longer a barrier.

Our Core Belief: Ingest First, Clean Later

Most consultants tell you: “Fix your data first, then we’ll help.” We take the opposite approach: Ingest First, Clean Later.

Why? Because messy data isn’t the exception—it’s the norm. In fact, only 53% of supply chain leaders rate their master data quality as “adequate.” That means half the industry is making decisions in the dark.

Our AI-driven pipeline connects directly to your systems—data lake, ERP, WMS—and ingests everything as-is. No prep work required. No massive cleanup project upfront.

The heavy lifting? That’s our AI’s job.

The xChangeFlow AI Transformation Engine

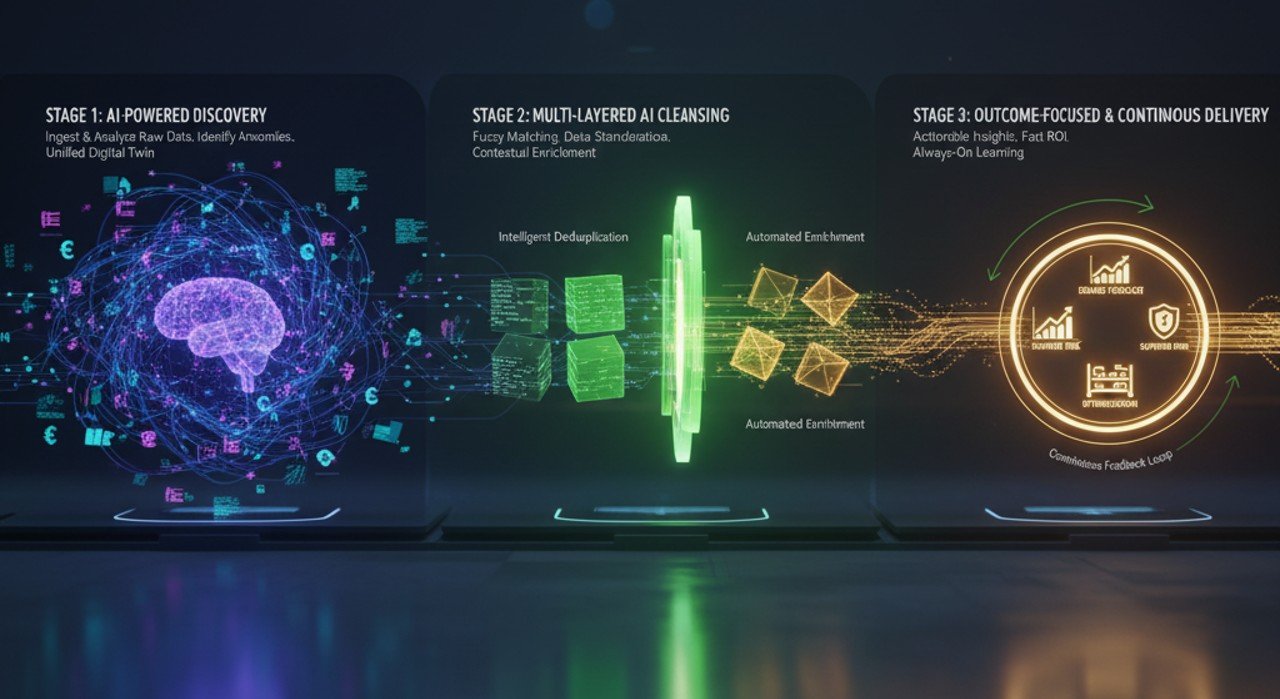

Stage 1: AI-Powered Discovery

Before fixing anything, we learn from your data. Our engine automatically:

Profiles anomalies and inconsistencies

Infers hidden connections (e.g., “5th Avenue” = “5th Ave”)

Unifies disparate records into a single, holistic view

Think of it as creating a digital twin of your supply chain—a real-time model of how your business actually runs, messy data and all.

Stage 2: Multi-Layered AI Cleansing

This is where transformation happens. Our approach doesn’t just apply static rules; it adapts intelligently:

- Intelligent Deduplication: Fuzzy matching merges duplicate products, suppliers, and customers—even across inconsistent spellings or IDs.

- Automated Enrichment: Missing fields are filled in, external data is added (like geocodes or market context), and your supply chain becomes richer and more insightful.

The stakes are high. Poor data quality costs organizations an average of $12.9 million a year—and in supply chains, even a single wrong address or procurement code can trigger costly ripple effects.

Stage 3: Outcome-Focused & Continuous Delivery

We don’t believe in “projects that never end.” Instead, we target high-value use cases first: inventory optimization, supplier risk, demand forecasting. That means ROI in weeks, not months.

And because the engine is always on, it keeps learning. Every correction a human makes feeds back into the system, so your data gets better continuously.

This continuous loop is key: supply chain leaders who break down silos and integrate operations see 20% higher efficiency rates.

The ROI: Why This Matters to You

When you stop waiting for perfect data, you start unlocking value immediately:

- Faster Time-to-Value – Insights in weeks, not quarters.

- Lower Costs – Skip the expensive cleanup projects. Remember: bad data can eat up 8–12% of annual revenue.

- Better Decisions – AI models trained on enriched, accurate data.

- Future-Proofing – A living supply chain data foundation that improves over time.

And the payoff is real: companies that successfully deploy AI in supply chains cut costs by 20% and boost revenue by 10%—but only if the data foundation is solid.

Your Data Lake is Already a Gold Mine

At xChangeFlow, we believe you don’t need “perfect data” to realize AI’s potential. You just need the right approach.

Your data lake is not a liability—it’s an untapped asset. Our AI-first methodology unlocks that value, transforming messy records into actionable intelligence for your supply chain.

Ready to turn your dirty data into supply chain gold? Let’s talk.